One Stop Destination for Printing Rubber Roller Manufacturer & Rubber Rollers Supplier in India

Precision and consistency in the world of printing mean everything – and Printing Rubber Rollers are vital to the attainment of both. These rollers provide easy transfer of ink, high-quality printing, and long life of equipment.

Being one of the most renowned Rubber Roller Manufacturers, Suppliers, we know how the correct roller construction and material would have a direct impact on the performance of printing machines in different industries.

What are Printing Rubber Rollers?

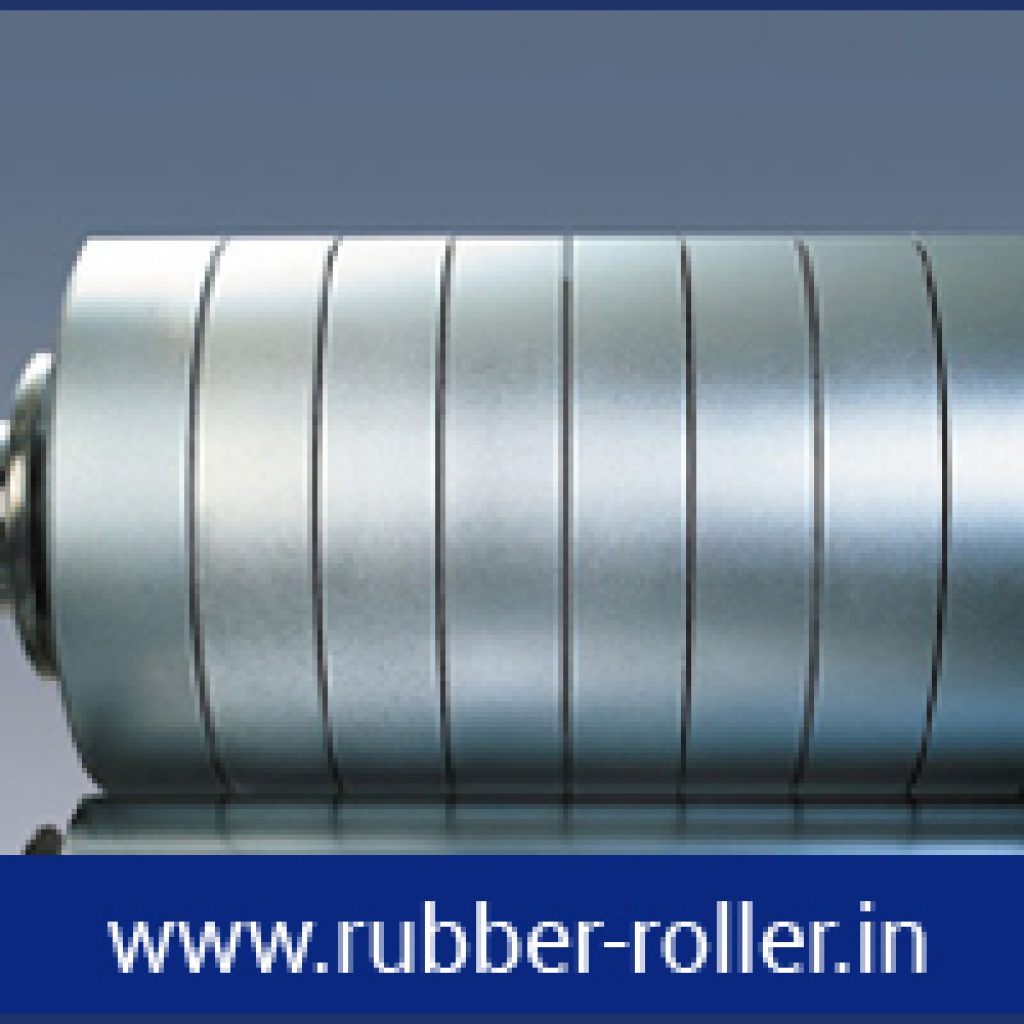

A Printing Rubber Roller is a cylindrically shaped item that is covered with rubber or other polymer substance, and is meant to transfer ink, force, or motion on a printing press. These rollers have been designed to be highly precise in order to provide consistency in the distribution of ink and high-quality print on various materials such as paper, film, or foil.

Printing Rubber Rollers are required in offset printing, flexographic printing, gravure printing, as well as digital printing machines, hence it is among the most sought-after components in the printing industry.

Types of Printing Rubber Roller

Ink Transfer Rollers

Provide a smooth and steady flow of ink on the printing surface.

Offset Printers Rollers

This is designed to use high-speed printing with high-quality ink balance.

Anilox Rollers (Flexo Printing)

Feature microcell engraving to store and dispense accurate amounts of ink.

Gravure Printing Rollers

High-quality image printing rollers that are frequently coated with special rubber compounds.

PU (Polyurethane) Rubber Rollers

They have great wear resistance and chemical resistance.

Bowed / Expander Rollers

Eliminate wrinkles and bubbles when printing a web.

Manufacturing Process of Printing Rubber Rollers

A Rubber Roller is a multi-stage production procedure, which defines its performance and duration of service. Major Rubber roller manufacturers adhere to modern production methods to retain quality and performance.

Core Fabrication

It starts with the manufacture of the roller core, which can be of mild steel, stainless steel, or aluminum. The core is turned to balance and dimension.

Surface Preparation

The core is cleansed and roughened in advance before coating, so as to give good bonding of rubber and metal.

Rubber Compounding

Nitrile (NBR), EPDM, Silicone, Neoprene or Polyurethane, high-grade rubber compounds are chosen depending on the printing needs, like the type of ink, its ability to resist solvents, and temperature limit.

Rubber Coating

The compound is extrusion or wrapped on the roller core in a uniform manner. Such a step assures proper thickness and hardness (durometer) to ease performance.

Vulcanization

The roller with the coating is subjected to heat curing or autoclaving, where the rubber gains the highest strength, elasticity, and adhesion.

Grinding and Finishing

The roller is then ground and polished after the curing, to provide an accurate surface finish, concentricity, and roundness - essential to uniform transfer of ink.

Quality Inspection

Lastly, rollers are checked on balance, hardness, accuracy in diameter, and surface finish, and then sent to clients.

Quality Standards Rubber Rollers

Printing Rubber Roller Manufacturer is a reputable company that has taken quality checks during manufacturing. It contains some of the important quality parameters:

- Proper rubber testing on the resilience of rubber on shore.

- Balancing at high speeds to avoid vibration.

- Roughness on the surfaces to control the flow of ink.

- Solvents and ink chemical resistance test.

- Dimensional accuracy to fit perfectly in the printing machine.

Following the international standards, the leading Rubber Roller Suppliers provide a longer roller life, higher quality of print, and shorter downtimes.

Applications

- Offset Printing Machines

- Flexographic Printing Units

- Gravure Printing Plants

- Printing and Coating Lines of textiles.

- All Packaging and Lamination Industries.

- Label and Film printing systems.

These rollers ensure uniform ink distribution, high image transfer, and smooth machine operation, which are essential in modern high-speed printing setups.

Why Choose Us?

The choice of a proper Rubber Roller Manufacturer or Rubber Roller Supplier is important in terms of long-term performance. Here’s why it matters:

- The ability to access personalized roller designs depending on your printing outfit.

- Premium rubber compounds that have better solvent and heat resistance are used.

- Accurate print technology to achieve enhanced print consistency.

- After-sales services and replacement services are fast and reliable.

- Bulk or custom pricing on a competitive basis.

The benefit of working with an established manufacturer is that you receive rollers that are perfect matches to your machine- you will have a better time in your production and save in terms of maintenance.

Rubber Roller Industry Growth

The Rubber Roller Market is growing steadily as it is getting increased demand because of the printing, packaging, textile, and paper industries. The growth of automation and quality demands in the printing processes is contributing to the development of long-life rollers in printing processes using high-performance materials and overcoating. With a well-known Rubber Roller Manufacturer, you will have access to these innovations for your business.

Printing Rubber Rollers are essential in the printing industry, whether in terms of improving the accuracy of the prints or achieving minimized downtimes. Selecting an appropriate Rubber Roller Manufacturer and Supplier means quality, durability, and maximum performance depending on your application requirements.

It is Industrial Rubber Rollers you need, PU Rubber Rollers you need, or even specialty Printing Rubber Rollers; reliable manufacturers will provide the same engineering excellence your business needs.