Rubber rollers, Rubber roller, Rubber roll, Rubber rolls, Rubber coating rollers, Rubber Coating Manufacturer, Rubber coated rollers, Rubber rollers manufacturers, Industrial Rubber rollers, rubber rollers suppliers, rubber metal bonding rollers, Rubber covered rollers, Industrial Rollers, Rubber rollers Exporters

No.1 Reputed Rubber Rollers Manufacturers & Exporters in Ahmedabad, India, Rubber Rollers Supplier

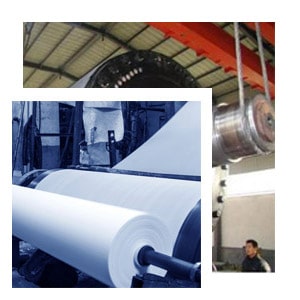

The Rubber Rollers are one of the most vital industrial components that are found in printing, packaging, textiles, paper, steel, plastic and laminating industries. This variety of rollers offers smooth operating, precision, and durability in heavy-duty applications.

High-performance Rubber Rollers are in high demand as the manufacturing industry in India continues to grow. The city of Ahmedabad, especially, has emerged as a prime destination for the Rubber Rollers manufacturers in the country, not only catering to the domestic industries but the global markets.

This guide explains all you need to know about Rubber Rollers: types, processes involved, technical specifications, uses, current trends, and choosing the supplier.

What are Rubber Rollers?

A Rubber Roller is a cylindrical part bounded by a core of metal as well as an elastomer layer (natural/synthetic rubber).

Functions of Rubber Rollers:

- pulling, pushing, and pinching

- Laminating and coating

- Moving the inks, films, or liquids

- Spreading, finishing, and guiding materials

The rubber rollers are designed and manufactured to mitigate heavy loads, maintain dimensional stability, and work in harsh industrial conditions.

How Process of Manufacturing a Rubber Roller Works?

A rubber roller production is a highly accurate and controlled process that guarantees stability, performance, and reliable production. Every roller passes a number of technical processes, which begin with the core preparation up to the final finishing. The manufacture of high-quality rubber rollers to be used in industry is described in detail in the steps below.

Step 1. Core Preparation

It starts with the choice and preparation of the metal core, which is mostly any of the metals: steel, aluminium, or cast iron.

- The core is cut into the preferred sizes.

- Better rubber bonding is provided by the addition of grooves or keyways.

- The surface cleaning, cleaning, and sandblasting are done to eliminate impurities.

Purpose: Excellent bonding between metal and rubber.

Step 2. Surface Treatment & Bonding

The metal core is then given a primer coating process after cleaning:

- This is enhanced with an adhesion primer.

- The rubber layer is supposed to bond firmly during the curing process, and bonding agents are utilized to accomplish this.

Purpose: deters delamination and enhances roller life.

Step 3. Preparation of Rubber Compounds

The various types of rubber employed in making rubber rollers include NBR, EPDM, Silicone, Neoprene, and SBR.

- Mixed in a mixing mill or kneader is the raw rubber mixed with fillers, chemicals, and colorants.

- The compound is kneaded until it becomes perfectly hard, elastic, and resistant to chemicals.

Purpose: Develop a quality rubber compound that can be used in the roller.

Step 4. Rubber on the Core

The rubber compound is usually placed on the prepared core with a variety of techniques:

- Uniform rubber application extrusion process.

- Wrapping sheets of calendering on the core.

- Precision-grade rollers that are to be molded or injected.

Purpose: Develops the necessary thickness of rubber over the metal core.

Step 5. Curing & Vulcanization

After the rubber has been applied, the roller is then put into a vulcanizer or autoclave.

- Chemical reactions occur by exposure to heat and pressure.

- This is done to have a solid rubber and to increase its mechanical strength.

Purpose: Improves the life of the roller, its elasticity, and heat-resistance.

Step 6. Precision Grinding & Sizing

The roller is also carefully ground when vulcanized:

- Excess rubber is removed.

- Taper, surface finish, and diameter are taken to precise tolerances.

- Special grinding machines guarantee even, smooth surfaces.

Purpose: The role is to achieve a perfect round and accurate size.

Step 7. Final Finishing and Quality Control

The roller is passed through before delivery:

- Surface finishing and polishing.

- Test of hardness and thickness.

- Dynamic balancing tests and concentricity tests.

- Checking of cracks, air bubbles, or defects by sight.

Purpose: Assures that the roller is of industry standard and specifications.

Step 8. Packing & Shipping

Lastly, finished rollers of rubber are packed with:

- Protective wrapping

- Wooden boxes or crates

- Moisture-resistant packaging

Purpose: Helps it not to being damaged in transit or storage.

Rubber Rollers First Wear Technical Features & Benefits

| Hardness | 20 – 100 Shore A |

| Load Capacity | Supports heavy-duty tasks |

| Temperature Resistance | 250 °C (Silicone Rollers) |

| Surfacing | Smooth/textured/grooved as per requirement |

| Bonding | Good sticking of the rubber and the metal core |

Benefits

-

Long service life & durability

-

wear, chemical, and heat resistance

-

High accuracy within the industry

-

Special application customization.

-

High accuracy within the industry

How do you Select the Right Manufacturer of a Rubber Roller?

- Experience and Expertise - Established track record over the years.

- Customization Capabilities - Capability to fabricate rollers to specific specifications.

- Materials Choices - Good selection of natural, synthetic, and silicone rubber.

- Certifications and Quality Standards - ISO, CE, or other quality symbols.

- After-sales support - Repair of rollers, re-covering them, and maintenance.

ADVANCE RUBTECH has become one of the most reliable companies in the world of the Rubber Roller Market in Ahmedabad, India, with the capability of modern technology, good pricing, and quality exporting.

Rubber Rollers play a very critical role in smooth industrial functioning, good output, and durability. State-of-the-art manufacturing techniques, hydraulic pressure moulding, and superior modern polymers mean that rollers are highly reliable and more efficient than they have ever been.

Ahmedabad, India, is regarded as one of the major centers of Rubber roller production that covers a wide range of industries worldwide.

To find the right Rubber Rollers manufacturers in India, choose one that displays technological savvy, specialized customization, and a track record of experience that matches your needs.

FAQs

With proper maintenance, Rubber Rollers can last 2 to 5 years, depending on how it is used and the material.

Manufacturers offer custom sizes and hardness levels as well as coatings to different industries.

Keeping rollers clean, without sharp materials and with proper roller alignment, will help prolong life.

Printing and packaging, textile, paper mills and plastics, and steel industries.

It makes it have a compact construction and bonding strength that makes rollers last longer.